עלעוואַטאָר גירלאָז טראַקשאַן מאַשין THY-TM-SC

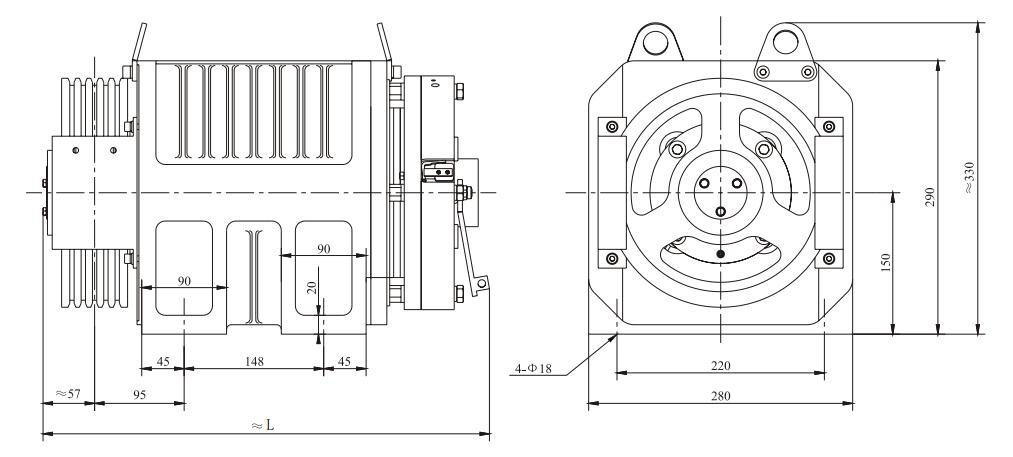

די THY-TM-SC גאַנגלאָזע טראַקשאַן מאַשין איז אויסגעשטאַט מיט אַ PZ300B ברעיק. ווען די טראַקשאַן שייוו איז קאָנפיגורירט מיט Φ320, איז די ברעיק PZ300C. די ברעיקס האָבן אַלע די CE סערטיפיקאַט אנערקענט דורך דער אייראפעישער פֿאַרבאַנד. באַזירט אויף דער זיכערהייט אַסעסמאַנט פון די קוואַליטעט פארזיכערונג סיסטעם, טרעפט עס די גרונט רעקווירעמענץ פון די LIFT דירעקטיוו און די כאַרמאָניזירטע סטאַנדאַרט EN 81-1 אין די פּלאַן, פּראָדוקציע, דורכקוק און טעסטינג לינקס. די טיפּ טראַקשאַן מאַשין קען ווערן גענוצט פֿאַר עלעוואַטאָרן מיט אַ לאַסט קאַפּאַציטעט פון 320KG~450KG און אַ רייטאַד גיכקייט פון 1.0~1.75m/s. די רעקאָמענדירטע עלעוואַטאָר הייך איז ≤80m. דער דיאַמעטער פון די טראַקשאַן ראָד קען ווערן אויסגעקליבן לויט באַניצער באדערפענישן. די לענג פון די מאַשין גוף ענדערט זיך מיט די דיאַמעטער פון די טראַקשאַן ראָד. ווען אויסגעשטאַט מיט אַ מאַשין צימער-לאָזער עלעוואַטאָר, כולל עס אַ ווייַט ברעיק מעלדונג מיטל און אַ 4m ברעיק מעלדונג קאַבל. איידער די טראַקשאַן מאַשין ווערט אינסטאַלירט, ניצט אַ 500 וואלט מעגאָהמעטער צו מעסטן די איזאָלאַציע קעגנשטעל פון די מאָטאָר ווינדינג און די ברעיק סאָלענאָיד שפּול. די איזאָלאַציע קעגנשטעל ווערט זאָל נישט זיין ווייניקער ווי 3 מעגאָהמס, אַנדערש זאָל עס זיין טרוקן; עס מוז זיין אונטער די סביבה באדינגונגען אַז די הייך זאָל נישט יקסיד 1000 מעטער. אין דער זעלביקער צייט, די אַמביאַנט לופט זאָל נישט אַנטהאַלטן קעראָוסיוו און ברענענדיק גאַזן; די פּערמאַנענט מאַגנעט סינטשראָנאָוס ליפט טראַקשאַן מאַשין מוז זיין פּאַוערד דורך אַ דעדאַקייטאַד פּערמאַנענט מאַגנעט סינטשראָנאָוס מאָטאָר ינווערטער, און קען נישט זיין גלייך פארבונדן צו די דריי-פאַסע מאַכט סיסטעם, און עס מוז אַרבעטן אין אַ פארמאכט שלייף קאָנטראָל מעטאָד, דעריבער, די גירלעסס טראַקשאַן מאַשין מוז זיין יקוויפּט מיט אַ ראָוטאָר שטעלע באַמערקונגען מעסטן מיטל (ענקאָדער). דער ענקאָדער פארלאנגט פֿאַר פאַרשידענע ינווערטערס איז אַנדערש. קאַסטאַמערז קענען קלייַבן לויט זייער אייגענע קאָנטראָל סיסטעם. די סטאַנדאַרט קאָנפיגוראַציע עס איז HEIDENHAIN ERN1387 ענקאָדער, און עס גיט אויך פאַרשידענע טייפּס פון שילדיד קייבאַלז פֿאַר ענקאָדערס. קאַסטאַמערז קענען קלייַבן זייער אייגענע פּערמאַנענט מאַגנעט סינטשראָנאָוס ליפט טראַקשאַן מאַשין לויט די לאַסט קאַפּאַציטעט, גיכקייַט און פּראָדוקט סעריע זיי דאַרפֿן, ווי געזונט ווי די פּאַראַמעטערס רעקאַמענדיד דורך די פירמע.

די מעטאָדע פון אַדזשאַסטירן די עפענונג שפּאַלט פון די ברעיק PZ300B/PZ300C:

געצייג: אן אפענער שליסל (16 מ״מ), פיליפּס שרויפנציהער, פילער מאס

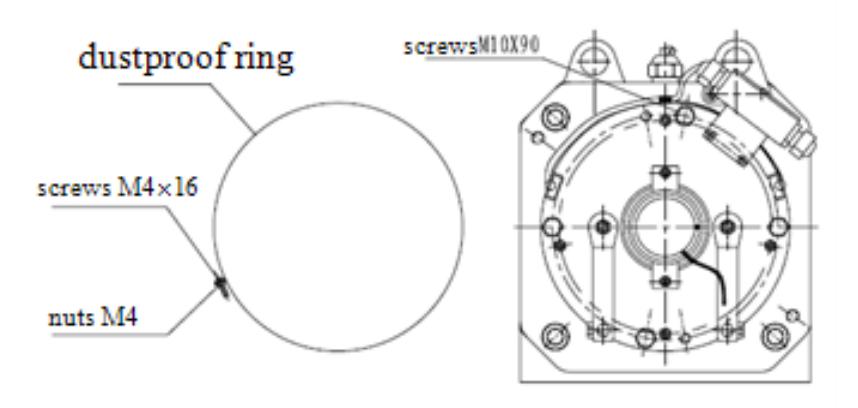

דעטעקציע: ווען דער ליפט איז אין פארקינג צושטאנד, ניצט א פיליפּס שרויפנציהער צו אפשרויפן די שרויף M4x16 און נוס M4, און נעמט ארויס דעם שטויב-האלטונג רינג אויף דער ברעיק. ניצט א פילער מאס צו דעטעקטירן דעם שפאלט צווישן די באוועגלעכע און סטאנציאנע פלאטעס (10°~20° פון דער קארעספאנדירנדיקער פאזיציע פון די 4 M10 באָלץ). ווען דער שפאלט איז גרעסער ווי 0.35 מ"מ, דארף מען עס צופאסן.

אַדזשאַסטמענט:

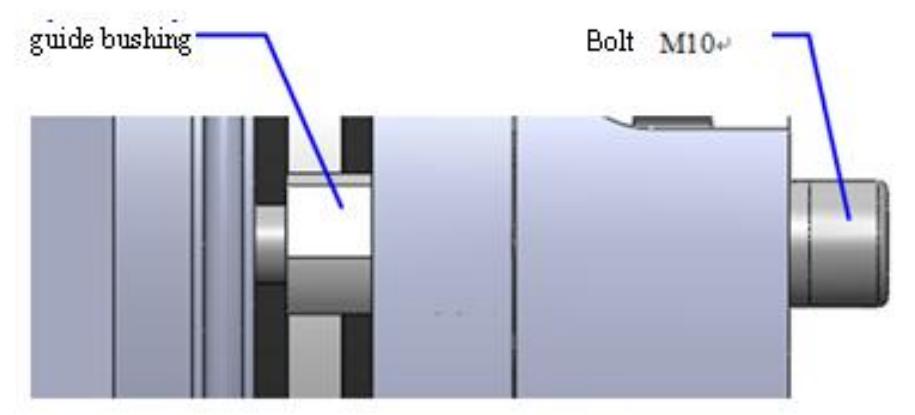

1. ניצט אַן אָפֿן-ענד שליסל (16 מ״מ) צו לאָזן לויצן דעם M10 באָלט פֿאַר אַרום אַ וואָך.

2. לאַנגזאַם אַדזשאַסטירן דעם ספּייסער מיט אַן אָפֿן-ענד שליסל (16 מ״מ). אויב דער שפּאַלט איז צו גרויס, אַדזשאַסטירן דעם ספּייסער קעגן זייגער, אַנדערש, אַדזשאַסטירן דעם ספּייסער מיט זייגער.

3. ניצט אַן אָפֿן-ענד שליסל (16 מ״מ) צו פֿעסטציען די M10 באָלץ.

4. ניצט ווידער א פילער מאס צו קאנטראלירן דעם שפאלט צווישן די באוועגלעכע און סטאטישע דיסקס צו זיכער מאכן אז עס איז צווישן 0.2 מ"מ און 0.3 מ"מ.

5. ניצט די זעלבע מעטאָדע צו סטרויערן די לעכער פון די אנדערע 3 פונקטן.

6. אינסטאלירט דעם ברעיק שטויב-דערווייַזן ריטיינינג רינג און באַפעסטיקט עס מיטן שרויף M4X6 צוזאַמען מיטן נוס M4.

וואָולטאַזש: 380V

סאַספּענשאַן: 2:1

PZ300B ברעיק: DC110V 1.6A

PZ300C ברעיק: DC110V 1.9A

וואָג: 140 ק"ג

מאַקס.סטאַטיש לאָוד: 1600 קג

1. שנעלע ליפערונג

2. די טראַנזאַקציע איז נאָר דער אָנהייב, דער סערוויס ענדיגט זיך קיינמאָל נישט

3. טיפ: טראַקשאַן מאַשין THY-TM-SC

4. מיר קענען צושטעלן סינקראָנישע און אַסינקראָנישע טראַקשאַן מאַשינען פון TORINDRIVE, MONADRIVE, MONTANARI, FAXI, SYLG און אַנדערע בראַנדז.

5. צוטרוי איז גליק! איך וועל קיינמאָל נישט פֿאַרלאָזן דיין צוטרוי!